Data Analytics as a tool to reduce the cost of production in Oil & Gas

Oil & Gas sector is one of the core industries of India and they play important role in influencing the decision making other sections of the economy. The government has taken many steps keeping in mind the increasing demand of the oil and gas, the government has allowed 100 percent Foreign Direct Investment in many sectors including natural gas, petroleum and many more, because of which it has attracted foreign and domestic investors like Reliance Industries Ltd and Cairn India.

Companies in oil and gas business also aim to achieve the similar goals that other industries are doing that is producing the product at low cost and selling it for the higher cost and making good profits, but for oil and gas companies owner its quite challenging, because finding and producing gas and petroleum are expensive. As oil and gas industry is working hard to meet the global demand of energy, there are many other challenges that industry faces a major external challenge that they face is the environment in which the upstream industry operates. Like always with challenges come opportunity, the opportunity for the upstream industry to reshape operations in which they work from reservoir to refinery, using Big data and Analytics, many companies are using these techniques as they help them to optimize their operations by reducing the cost and increasing the productivity thereby helping in making profits. A recent study by Kimberly firm, they found out that offshore oil and gas industries lose $49 million annually due to unplanned downtime and for some companies it’s up to $88 million, by using big data and analytics companies can save up to 20% in their capital expenditure and can cut upstream cost by 3-5%. A study by Bain & Company indicates that harnessing Big Data with analytics in the oil and gas industry could help them improve production by 6% to 8%. Better data analytics can improve the ability to find the product, reduce the cost of development and production, and make energy more affordable and safer to extract.

The operator can incorporate big data solutions using Retrofits equipment sensor, it can have a very fast payoff in terms of reducing maintenance cost and increasing reliability. Connecting the cloud, using Asset Performance Management (APM) software powered by GE’s Predix is a suite of software that connects upstream assets to the digital world, using this software companies can get informative data from their sensors, which will help them improve their operations, which will effectively help in reducing the cost of production. IOT and PREDICTIVE BIG DATA ANALYSIS can be used in the oil and gas sector for maintaining and making proper models that are easy to be optimized, software like LAS log analytics can are used with HDP big data analytics for oil and gas allows scientists to ingest and query their disparate LAS data for use in predictive models. They can do this while leveraging existing statistical tools such as SAS or R to build new models and then rapidly iterate them with billions of measurements. Combining LAS data with production, lease, and treatment data can increase production and margins.

The statistical tool like SAS can be very efficient in oil and gas industry; it’s used from planning to production in every stage, from countering the risk of cost inherent in oilfield exploration to Improving reserve exploration strategies. It can help in finding the uncover hidden patterns in the data by revealing the connection not evident before linking all the data to each other. SAS can help in Seeing the full picture by adopting a data integration platform that aggregates data from exploration, drilling, completion, reservoir, production and more, helping in taking the right decision and optimizing the production and reducing the cost.

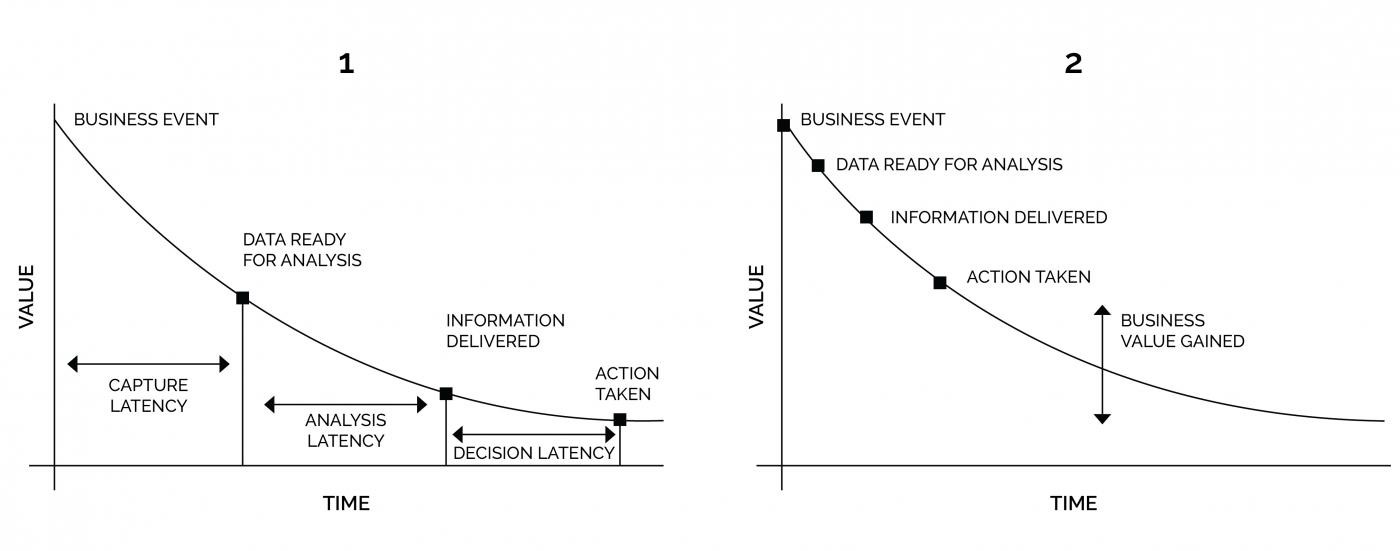

There are so many technologies available which help in saving time and cost on of which is Real-Time Data, real-time data focus on how to drive better insight from data quicker than ever in real time.

Real-Time data at well site help in reducing the decision latency curve (Source: Mobilize).

Leading Oil & Gas companies have already begun projects in which they are using Big Data technologies. Which is helping them to track new business opportunities, reduce costs and increase in production.

By recognizing the value of the unexploited data assets in supporting fact-based decision making, Oil & Gas companies establish real cases of Big Data uses. So that they can enhance their Business value based on innovation and able to lead towards a sustainable competition.

Over the coming years, the industry will be defined by those who will take advantage of digital and analytics to evolve. Investing in these will help digital to deliver better efficiency and productivity, for the brighter future of the industry.

Blackcoffer Analytica, Ravi Kumar